Smart DRS – An Efficient Deposit Return Scheme

- 21. January 2022

- Blog

A well-designed Smart Deposit Return Scheme (DRS) is based on understanding the local situation and key processes while considering lessons learned from other countries.

A deposit return scheme is a series of processes that involve numerous parties. Whether a country can establish an environmentally and cost-effective DRS depends on how efficiently the operator monitors and manages these processes. Drawing on its long-term experience in the market, RLG has built an integrated management system and promotes a well-designed Smart DRS to manage deposit systems holistically and end-to-end.

The smart approach to DRS builds on the traditional DRS developed by RLG in the early 2000s. It considers its beneficial aspects and experiences (e.g., ensuring material quality) and addresses drawbacks and learnings from conventional DRS. A well-designed DRS needs to meet local market requirements, harness efficiency potentials, and employ new technologies commonly used in other industries, such as data matrix codes for digital marketing or product traceability. Choosing RLG’s proposed solution, the deposit scheme will support recycling targets more cost-effectively. Additionally, it is open to system expansions, and further developments should the need arise in the future.

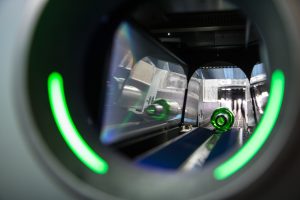

A deposit scheme is more than a reverse vending machines (RVMs) network. First and foremost, it is a system of stakeholders and relations between them. Therefore, it must enable effective and flexible communication between system participants and their applications such as manufacturers, logistics companies, collection infrastructure including producers of RVMs and other technologies, POS (Point of Sale) systems located at retail collection points, and government systems for reporting purposes.

At RLG, we work with various partners and subcontractors, which translates into our ability to integrate equipment and machines from different suppliers and manufacturers into our system. This, in turn, gives the system operator the freedom to put the collection, logistics, and recycling infrastructure out for tender – says Marcel Rakowski, EVP Corporate Development at Reverse Logistics Group

As consumer behavior changes, Smart DRS enables collection beyond “return to retail” without being limited to RVMs, which, despite their undeniable advantages, cannot be used everywhere. Besides RVMs, Smart DRS allows the application of various collection methods that are easy to implement in small stores, municipal offices, and even outside. So, anywhere consumers are, ensuring the highest quality of materials suitable for recycling. Furthermore, contrary to the manual collection used in current deposit systems, DRS also offers to crush the collected materials, which significantly reduces the cost of logistics.

In our proposed solution, we also provide an opportunity to build a deposit scheme that is more accessible for consumers. Given the structure of retail and residence in many countries, it would be a mistake to limit the possibility of returning packaging only to large stores. This constraint could be a consumer convenience issue and concern for smaller retail store owners. Suppose we broaden our perspective and base the Polish deposit system on a solution that can be implemented in any store, even a small one. We would create a fair system without promoting supermarkets. On the other hand, if a deposit scheme is only accessible in a few stores, we would unintentionally distract customers who, instead of returning their bottle to a nearby store and shopping there, would do both in a supermarket. And this would undoubtedly be to the detriment of small local shopkeepers – Rakowski adds.

Moreover, the Polish deposit system based on the Smart DRS approach would offer complete data collection, allowing processes to be monitored and continuously optimized. This ongoing refinement translates into economic and environmental effects and makes it possible to accurately calculate costs for those who put packaged products on the market.

Tracking packaging placed on the market is not science fiction – it’s a technological standard in many industries. It also brings several financial benefits to stakeholders of the process, such as generating valuable data and minimizing the potential for fraud in current systems – Rakowski states.

Smart DRS is not necessarily an alternative but an extension to the conventional deposit return schemes and prepares them for future challenges and needs. For example, Smart DRS makes it easy to extend deposit schemes to include other types of packaging, regardless of their shape, which paves the way for collecting multi-ply board packages for liquid food (e.g., milk or juice).

We need to recall that we have been building a system for 10–15 years. Our approach is future-oriented with possibilities for further extensions, and at the same time, it is compatible with all deposit schemes currently in use. Smart DRS integrates information about the material and financial flows in one application. The data it collects allows for constant improvements to the deposit system without a lock-in effect, as Marcel Rakowski points out.